Comprehensive Overview High Voltage Porcelain Fuse Cutout

The High Voltage Porcelain Fuse Cutout is an essential component of electrical distribution systems, designed to protect power lines and equipment from overloads and short circuits. It plays a crucial role in ensuring the safety and reliability of electrical networks, particularly in high voltage applications.

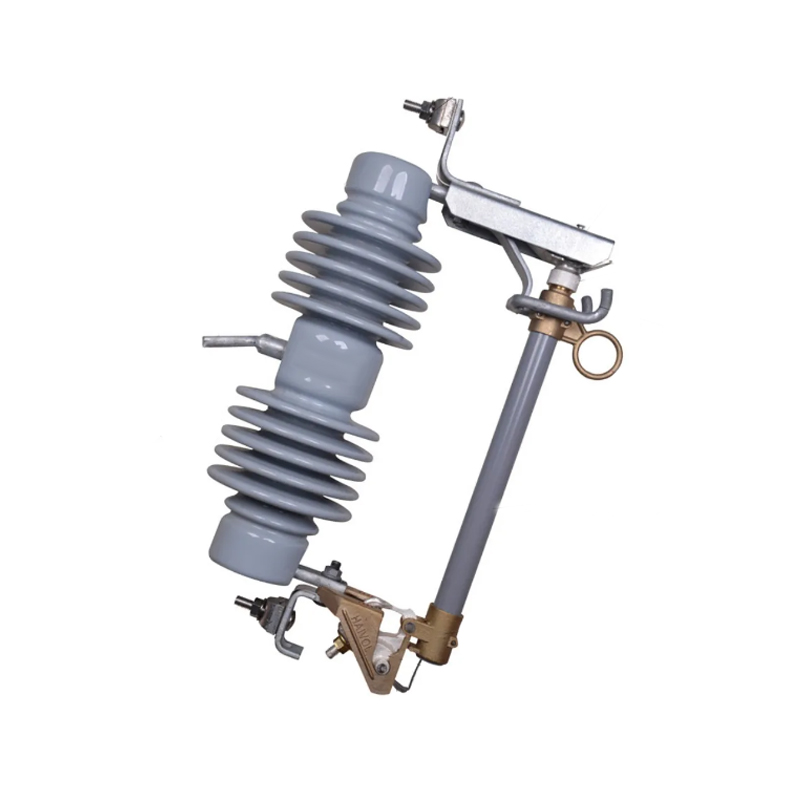

The High Voltage Porcelain Fuse Cutout typically consists of three main parts: the insulator, the fuse holder, and the operating mechanism. These parts work together to interrupt the flow of current in the event of an overcurrent or short circuit.

Insulator: Made of high-grade porcelain, the insulator provides excellent electrical insulation and mechanical strength. It supports the entire assembly and keeps it securely attached to the power line.

Fuse Holder: Positioned on the lower end of the insulator, the fuse holder houses the fuse element. It's constructed to withstand high electrical currents and effectively contain any arc that may occur during fuse operation.

Operating Mechanism: The operating mechanism enables the controlled operation of the fuse cutout. It includes a mechanism for manual or automatic tripping, allowing for the quick and reliable interruption of current flow when necessary.

The fuse cutout remains closed, allowing electricity to flow through the power line without impedance. However, when an overcurrent or short circuit occurs, the current passing through the fuse exceeds its rated capacity. This excessive current causes the fuse element to melt, creating an air gap and interrupting the circuit.

High Voltage Porcelain Fuse Cutouts are commonly used in distribution systems, particularly in areas where high voltage levels are present. They are installed on overhead power lines, transformers, and other critical infrastructure to safeguard against electrical faults and maintain system reliability.

Safety: By promptly interrupting fault currents, fuse cutouts help prevent electrical accidents and protect personnel and equipment from harm.

Reliability: These devices contribute to the overall reliability of electrical networks by small downtime and reducing the risk of prolonged outages.

Versatility: Available in various voltage ratings and configurations, fuse cutouts can be tailored to suit specific application requirements.

The Role of Cover Drop Out Fuse in Distribution Systems

Cover Drop Out Fuse, also known as Dropout Fuse, is a crucial component in electrical distribution systems, particularly in overhead lines. It serves as a protective device against overloads and short circuits, safeguarding equipment and ensuring the uninterrupted flow of electricity.

The Cover Drop Out Fuse comprises several key components designed to facilitate its operation effectively:

Fuse Element: Located within the fuse tube, the fuse element is typically made of a high-conductivity material such as silver or copper. It is engineered to melt quickly when subjected to overcurrent conditions, thus interrupting the electrical circuit.

Fuse Tube: Constructed from durable materials such as porcelain or polymer, the fuse tube encases the fuse element, providing insulation and mechanical protection. It also helps contain any arc that may occur during fuse operation.

Cover Assembly: The cover assembly consists of a hinged cover attached to the fuse tube. It serves as a protective barrier, shielding the fuse element from environmental factors such as moisture, dust, and debris.

Operating Mechanism: Some Cover Drop Out Fuses feature an operating mechanism that allows for manual or automatic tripping. This mechanism facilitates the controlled opening of the fuse under fault conditions, ensuring swift interruption of current flow.

Under normal operating conditions, the Cover Drop Out Fuse remains closed, allowing electricity to flow through the circuit uninterrupted. However, when the current exceeds the rated capacity of the fuse element due to an overload or short circuit, the fuse element rapidly heats up and melts. This action creates a gap in the circuit, effectively isolating the faulty section and preventing further damage.

Cover Drop Out Fuses find widespread use in overhead distribution lines, transformers, and other electrical equipment. They are vital for protecting infrastructure and small downtime in the event of electrical faults.

English

English русский

русский عربى

عربى