Choosing the Correct type of load break switches is essential for ensuring reliable operation in modern electrical distribution networks. Two common types of load break switches are vacuum and SF6 gas-insulated switches. Qinghang Electric Co., Ltd., a professional manufacturer of outdoor load break switch and high voltage load break switch, offers both vacuum and SF6 load break switches suitable for various high voltage applications.

1. Arc Quenching Mechanism

The primary difference between vacuum and SF6 load break switches lies in the arc quenching method:

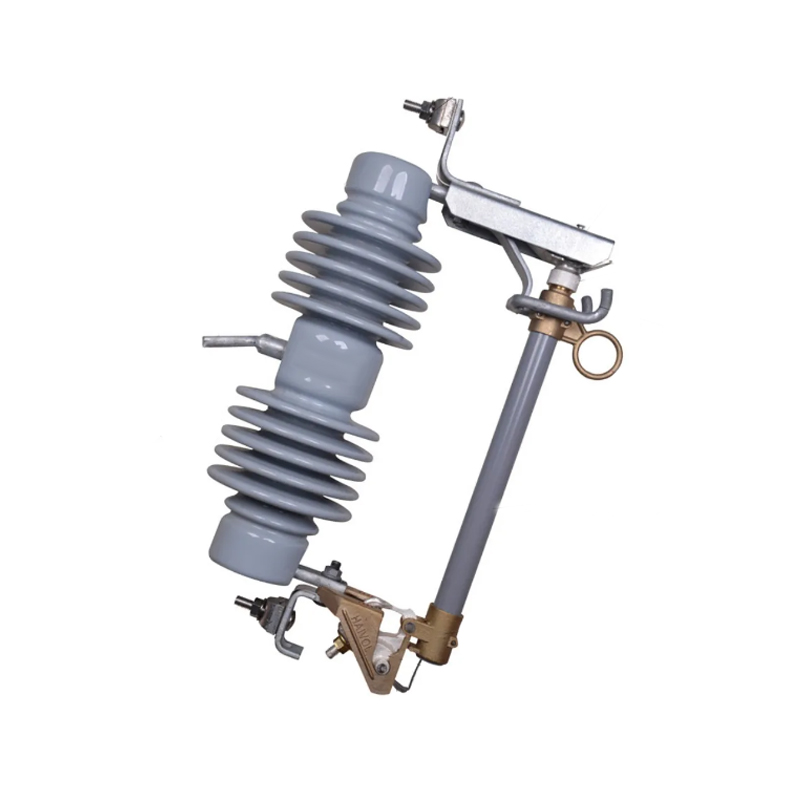

Vacuum Load Break Switch: Uses a vacuum interrupter to extinguish the electric arc. The vacuum provides high dielectric strength and prevents arc formation after contact separation. Vacuum switches are compact, lightweight, and suitable for medium voltage and some high voltage applications.

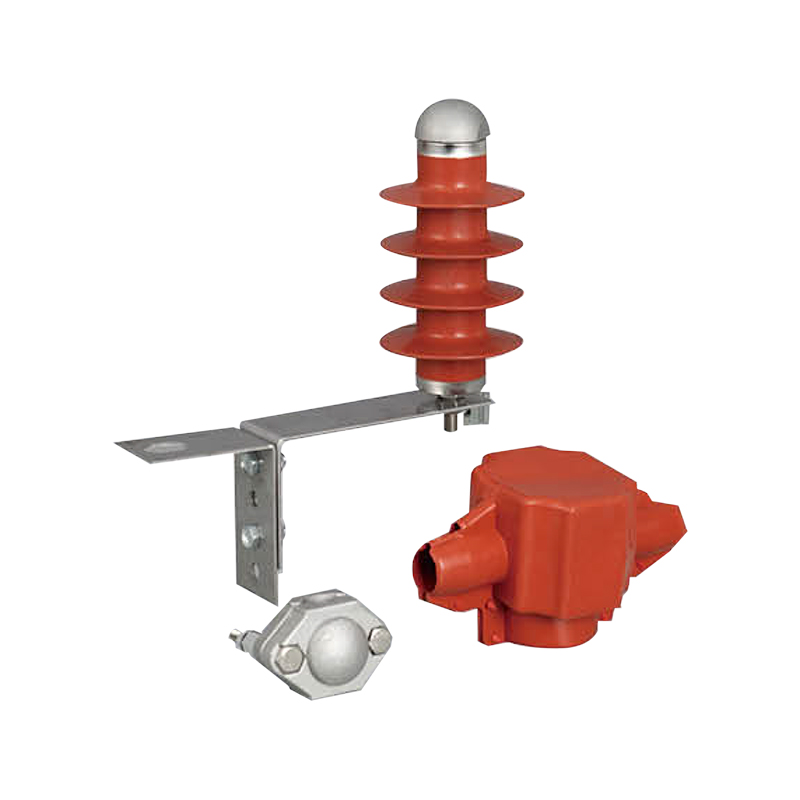

SF6 Load Break Switch: Uses sulfur hexafluoride gas as an insulating and arc-extinguishing medium. SF6 gas can handle higher voltages and provides good insulation, making these switches suitable for high voltage networks above 36kV.

Both types ensure safe interruption of load currents but are designed for different system requirements.

2. Installation and Space Requirements

Outdoor Load Break Switches with Vacuum Interrupters are smaller and easier to install, making them suitable for space-limited substations or pole-mounted applications.

SF6 Load Break Switches require larger enclosures due to the gas insulation system. Proper sealing is essential to prevent leakage and maintain insulation performance. Qinghang Electric Co., Ltd. provides compact and modular designs for both vacuum and SF6 switches to adapt to different installation environments.

3. Maintenance Considerations

Vacuum Switches typically require less maintenance because the vacuum interrupter is sealed and does not degrade under normal operation. Mechanical components like operating mechanisms may need periodic lubrication.

SF6 Switches require monitoring of gas pressure, leak detection, and periodic maintenance to ensure the gas maintains proper insulation. Proper maintenance ensures reliable performance and extends service life.

4. Environmental and Operational Factors

Vacuum Switches are generally robust against temperature variations and moderate pollution levels.

SF6 Switches are preferred in high-voltage networks with higher pollution, humidity, or more challenging environmental conditions, as the gas provides good insulation and arc suppression.

Both types of high voltage load break switches are designed to withstand outdoor conditions, including rain, dust, and high temperatures.

5. Application Scenarios

Medium Voltage Distribution: Vacuum load break switches are ideal for urban or industrial networks requiring compact switches with lower maintenance.

High Voltage Transmission: SF6 load break switches are suitable for substations and overhead line networks where higher voltage ratings and robust insulation are required.

Industrial Installations: Combining both types can optimize reliability, maintenance schedules, and operational efficiency.

6. Choosing Between Vacuum and SF6

When selecting a switch, consider:

Voltage Rating: Higher voltages may favor SF6 switches.

Space Limitations: Vacuum switches are smaller and easier to install.

Maintenance Capacity: SF6 switches require monitoring and preventive maintenance.

Environmental Conditions: Choose based on pollution, humidity, and temperature extremes.

Qinghang Electric Co., Ltd. offers expert guidance on selecting the more suitable load break switch type, ensuring good operation and compliance with international standards.

By selecting the Correct outdoor load break switch, engineers can improve system efficiency, reduce maintenance costs, and ensure secure electrical distribution. Qinghang Electric Co., Ltd. provides a wide range of vacuum and SF6 load break switches with certified quality and technical support, making them a trusted choice for various high voltage applications.

English

English русский

русский عربى

عربى