Unplanned circuit trips are a frequent operational headache for electrical teams managing MV & LV switchgear installations within MV and LV power distribution networks. Although switchgear is designed to protect electrical circuits from overloads, short circuits, or ground faults, unwanted trips still occur and disrupt facility operations. In commercial buildings, factories, data centers or any critical infrastructure, understanding why low voltage switchgear trips — and how to fix it — is essential to both system uptime and personnel safety.

1. Circuit Breaker Trips Due to Overcurrent or Overload

One of the more common reasons an LV switchgear breaker trips is an overcurrent condition. When the electrical current flowing through a circuit exceeds the breaker's rated capacity, protection devices intervene to stop potential damage. This can happen due to:

Loads that exceed the circuit’s design capacity.

Sudden surges from large motor starts or inrush current.

Multiple equipment running simultaneously on the same feeder.

When a breaker repeatedly trips, it’s important to evaluate the load distribution and compare it with the rating of breakers and feeders. In some cases, redistributing loads across additional circuits or balancing phases can reduce stress on individual breakers and prevent nuisance trips.

2. Short Circuit and Ground Fault Protection Activation

Circuit breakers trip quickly when they detect a short circuit or a ground fault. These protective actions occur because:

A short circuit creates an abnormally high current that threatens insulation and conductor safety.

Ground faults allow current to escape to earth, which can occur when degraded insulation or moisture bridges live parts to grounded surfaces.

If LV switchgear repeatedly trips at unexpected times, crews should inspect downstream cable insulation, check for exposed conductors, and use insulation resistance testing to identify compromised wiring. Visual inspection often reveals burn marks or component discoloration near fault points.

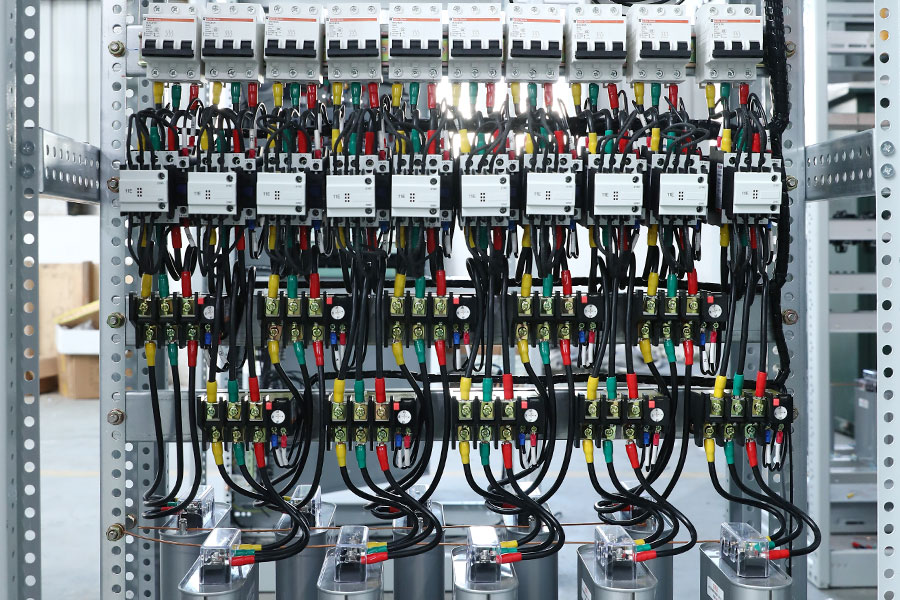

3. Loose Connections and Contact Resistance Issues

Loose or poor connections within switchgear busbars, terminals, or cable lugs increase electrical resistance. As resistance rises, localized heating occurs — which can both trigger trips and accelerate deterioration of components. These issues are typically flagged by:

Overheating markers such as discoloration or burnt insulation.

Intermittent trips that correlate with load changes.

Unusual hot spots found during thermal imaging inspection.

Tightening all power connections to recommended torque values and performing periodic infrared checks are effective measures to reduce these risks.

4. Insufficient Ventilation and Environmental Stress

LV switchgear generates heat during normal operations, especially when running near rated capacity. Without sufficient airflow, this heat can accumulate and cause protective devices to trip due to thermal stress. Contributing environmental factors include:

Poorly ventilated switchgear rooms.

Enclosures installed in spaces with high ambient temperatures.

Dust, humidity, or corrosive contaminants entering the panel.

Ensuring adequate ventilation and sealing switchgear properly against environmental ingress can mitigate overheating. Regular cleaning to remove dust and moisture absorbers in humid environments also support stable operation.

5. Mechanical and Component Wear Impacting Trip Behavior

LV switchgear contains mechanical components like contactors, interlocks, and operating mechanisms whose wear over time can interfere with expected performance. When moving parts are worn, they may:

Fail to seat properly under load.

Cause delayed or unreliable trip actions.

Trigger false trips when vibration or minor movement occurs.

Regular inspection, lubrication of moving parts, and replacement of worn components are key practices in avoiding trips caused by mechanical degradation.

6. Protection Relay Sensitivity and Coordination Issues

Sometimes the root cause lies not within the breaker itself but in associated protective relays. Incorrect relay settings — or mismatches between upstream and downstream protection devices — can cause unnecessary tripping or failure to trip when actually needed. Checking protection curves and ensuring proper coordination is essential for stable mv and lv power distribution operation.

LV switchgear trips are not just inconvenient — they can signal underlying stress in your electrical system. By identifying whether the trip originated from overloads, short circuits, environmental conditions, mechanical wear, or protection coordination issues, you can take corrective action that improves system reliability and reduces downtime. Regular testing, proper load planning, and preventive maintenance are all part of a proactive electrical management strategy. When equipped with these insights, teams responsible for mv & lv switchgear can maintain more resilient power distribution infrastructure and extend the service life of their equipment.

English

English русский

русский عربى

عربى