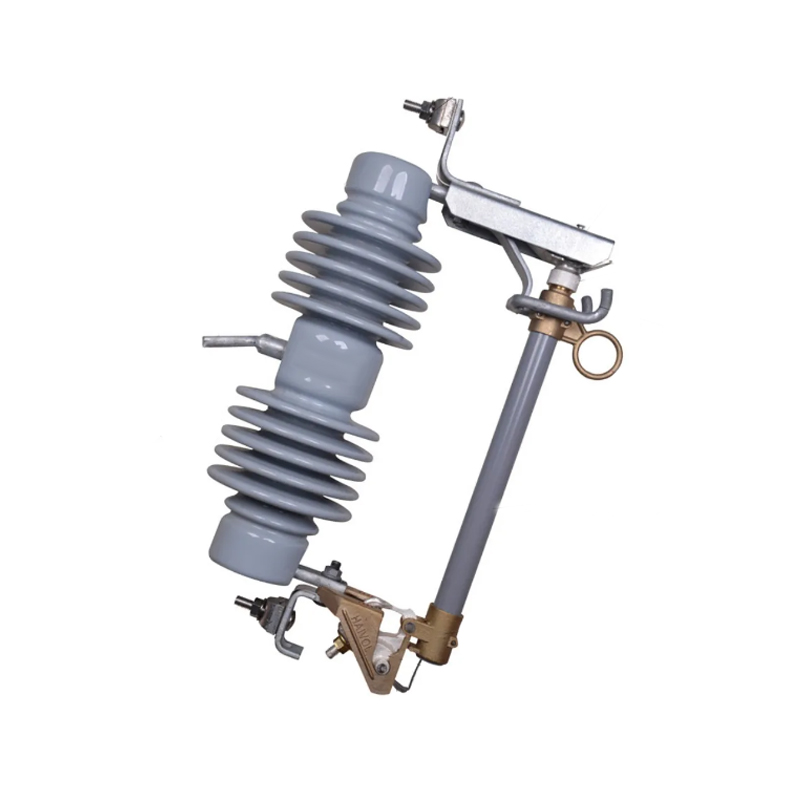

Ensuring the reliability and durability of Medium Voltage (MV) Power Distribution Switchgear is paramount for the secure and efficient functioning of electrical systems. These components are pivotal in managing, safeguarding, and disconnecting electrical circuits, particularly in industrial settings where electrical malfunctions can result in significant operational disruptions and equipment damage. To extend the service life of MV Power Distribution Switchgear, a consistent maintenance regimen is indispensable.

A straightforward yet highly effective maintenance strategy involves routine visual assessments of the switchgear. Look for indications of wear, corrosion, or damage, with a focus on the enclosure, busbars, and circuit breakers. Environmental factors like moisture, dust, and temperature severes can result in degradation over time, potentially causing operational difficulties or system failures.

It is crucial to scrutinize the switchgear for any loose connections or parts that have seen better days, as these can heighten the risk of overheating and electrical malfunctions. Additionally, verify that seals and gaskets are in good condition to prevent the ingress of contaminants that could compromise the switchgear's integrity.

Accumulation of dust, dirt, and other environmental particles within MV Power Distribution Switchgear can impair its performance. Regular cleaning is essential to avert the accumulation of conductive materials that might result in short circuits or other electrical issues. Employ suitable cleaning techniques, such as compressed air or specialized cleaning wipes, to clear dust from sensitive areas without causing damage to the equipment.

Protective relays in MV Power Distribution Switchgear are responsible for detecting electrical faults, such as overloads or short circuits, and triggering the necessary actions to protect the system. Regular testing of these relays is crucial to ensure they are functioning correctly.

Test the relays for proper calibration and operation at periodic intervals. Relay testing ensures that the switchgear can quickly and accurately respond to faults, reducing potential damage to the equipment and increasing the overall reliability of the system.

Temperature and humidity levels can significantly impact the performance of MV Power Distribution Switchgear. Excessive heat can cause components to overheat, reducing their lifespan and increasing the likelihood of failure. Similarly, high humidity can result in the formation of moisture within the switchgear, which can cause corrosion and electrical shorts.

To extend the life of the switchgear, it is essential to maintain the appropriate operating temperature and humidity levels within the equipment's enclosure. Regularly monitor temperature and humidity, and ensure that the ventilation system is working effectively. If necessary, use dehumidifiers or cooling systems to control the environmental conditions around the switchgear.

Circuit breakers are among the critical components of MV Power Distribution Switchgear. They serve to disconnect electrical circuits in the event of a fault, protecting both the switchgear and the connected equipment. Over time, circuit breakers can wear out or become less effective, especially in environments with frequent electrical disturbances.

Many types of MV Power Distribution Switchgear include moving parts, such as switches, circuit breakers, and disconnects. These components require lubrication to reduce friction and prevent wear. Lack of lubrication can result in increased mechanical resistance, resulting in overheating and premature failure.

The insulation system within MV Power Distribution Switchgear ensures that electrical current flows safely through the system without leakage or unintended grounding. Over time, the insulation can degrade due to age, moisture, or other environmental factors, increasing the risk of electrical faults.

Maintaining the health of MV Power Distribution Switchgear is essential for ensuring the safety, reliability, and longevity of power distribution systems in industrial environments. Regular inspections, cleaning, testing of protective relays, and monitoring of environmental conditions are vital practices to extend the service life of the switchgear. Proper maintenance not only reduces the risk of unexpected breakdowns but also helps to improve system efficiency, reduce operational costs, and prevent costly downtime. By following these maintenance tips, industries can ensure their MV Power Distribution Switchgear remains in ideal condition for many years, safeguarding both personnel and equipment.

English

English русский

русский عربى

عربى