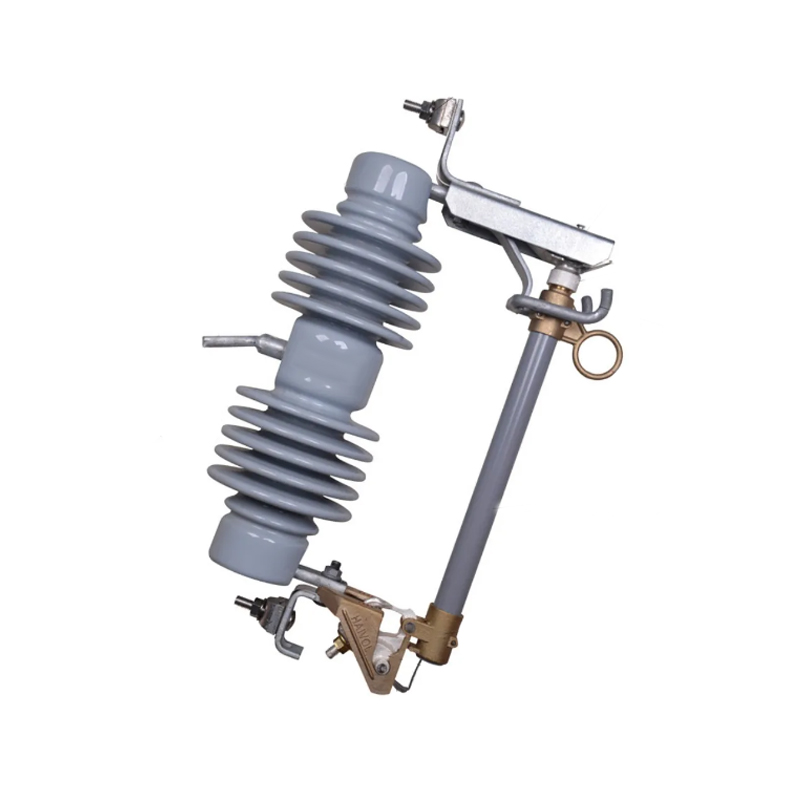

At Qinghang Electric, we emphasize the importance of regular maintenance to maximize the performance and lifespan of these devices. MV Power Distribution Switchgear is a core component in modern electrical networks, responsible for the safe and efficient distribution of electricity. Similarly, SF6 RMU (Ring Main Units) is widely used in compact distribution networks due to their gas-insulated design and reliability. Both types of equipment play a critical role in ensuring an uninterrupted power supply and protecting the system from faults.

Neglecting maintenance can cause overheating, insulation degradation, and even unplanned outages, which could result in operational losses for industrial or commercial facilities.

Why Regular Maintenance Matters

Enhancing Equipment Reliability

Regular inspections help detect potential issues such as worn contacts, corroded terminals, or partial discharges before they escalate. For MV switchgear, this prevents sudden breaker trips and system instability. For SF6 RMUs, monitoring gas pressure and detecting small leaks ensures that the equipment remains operational under all conditions.

Safety for Operators and Equipment

MV switchgear and SF6 RMUs handle medium-voltage currents, which can be dangerous if the equipment is compromised. Maintenance routines verify the functionality of safety interlocks, grounding systems, and protective relays, reducing the risk of accidents.

Compliance with Standards

Proper maintenance helps facilities meet regulatory requirements and industry standards, such as IEC and IEEE guidelines. For SF6 RMUs, maintaining gas integrity and insulating properties ensures compliance with environmental and safety regulations.

Key Maintenance Practices

Scheduled Inspections

Conduct visual and mechanical inspections at regular intervals to check for physical damage, loose connections, or abnormal wear.

For SF6 RMUs, inspect the gas compartments and pressure indicators to confirm that gas density remains within operational limits.

Electrical Testing

Perform insulation resistance tests, contact resistance measurements, and functional tests on breakers and relays.

Detecting deviations early allows timely corrective actions, preventing unexpected equipment failures.

Cleaning and Lubrication

Dust, dirt, and moisture can compromise electrical contacts and mechanical operations.

Clean the interior components and apply appropriate lubricants to moving parts, ensuring smooth operation and reducing wear.

Documentation and Record-Keeping

Maintain detailed logs of inspection results, repairs, and component replacements.

Track trends over time to identify recurring issues, improving predictive maintenance strategies.

Advanced Maintenance Tips

Thermal Imaging

Using infrared cameras can detect hotspots in switchgear, which often indicate loose connections or overloaded components.

Partial Discharge Monitoring

For SF6 RMUs, advanced monitoring systems can detect partial discharges early, preventing major insulation failures.

Operator Training

Educating personnel on proper operation, emergency procedures, and maintenance protocols ensures safe and efficient handling of both MV switchgear and SF6 RMUs.

Benefits of a Comprehensive Maintenance Program

Reduced Downtime: Early detection and correction of issues prevent unplanned outages.

Extended Equipment Lifespan: Regular care reduces wear, delays aging, and protects costly assets.

Cost Savings: Fewer emergency repairs and improved operational efficiency lower overall maintenance costs.

Improved Safety: Verified protective features minimize the risk of accidents to personnel.

At Qinghang Electric, we understand that regular maintenance of MV Power Distribution Switchgear and SF6 RMUs is crucial for operational efficiency, reliability, and safety. Implementing a structured maintenance program not only protects your equipment but also ensures stable and uninterrupted power distribution. By combining scheduled inspections, electrical testing, environmental monitoring, and operator training, companies can maximize the performance and lifespan of their switchgear systems while minimizing risks and costs.

English

English русский

русский عربى

عربى